taReo®: automation of thin film deposition

taReo is an advanced software tool designed to aid in the production of multilayer optical coatings in deposition chamber equipped with broadband optical monitoring (BBM). The BBM spectrometer records inline transmittance or reflectance data of a sample (test glass or a chip) positioned alongside the substrates within the deposition facility.

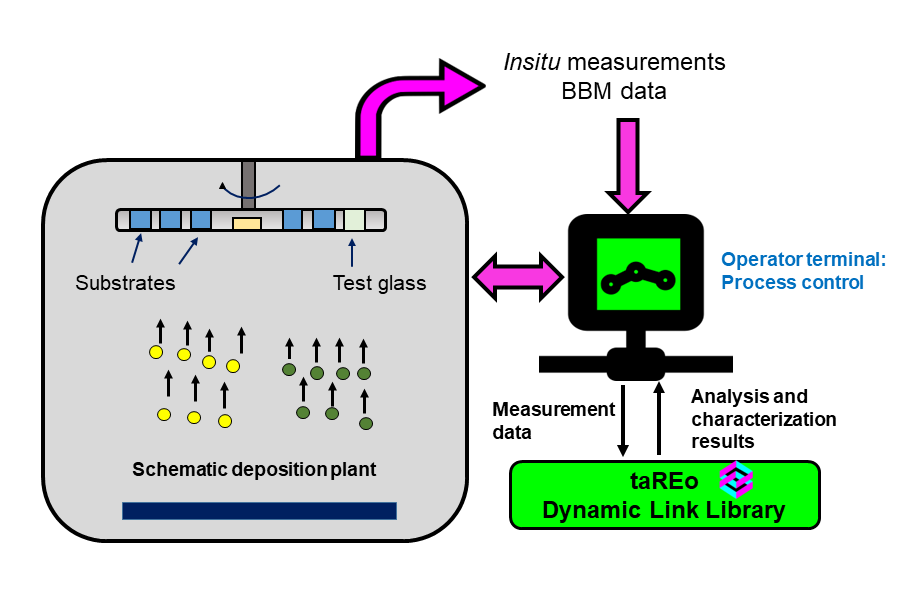

Fig. 1 illustrates a simplified diagram of the deposition plant featuring the inclusion BBM and taReo. Following the deposition of each coating layer, BBM device captures measurement scans. Additionally, BBM device has the capability to measure spectral properties throughout the entire deposition process at regular intervals.

taReo algorithms can be utilized to analyze the continuous data flow of inline measurements, to characterize previously deposited layers and the subsequent optimization of the remaining layers.

Fig. 1. Schematic of a deposition plant equipped with BBM and taReo.

- Deposition processes running under BBM control offer flexibility in their organization. One approach involves the direct measurement of spectral characteristics on the actual sample being produced using the BBM device. Alternatively, witness chips can be employed during the deposition process. When utilizing witness chips, there are multiple strategies available for determining when and how to replace them throughout the deposition process.

-

BBM device conducts inline measurements, covering a specific spectral range using the spectrometer integrated within the device. The spectrometer in modern devices is capable of measuring at several hundred wavelength points, providing a detailed analysis. BBM measurements are performed inline over a spectral range at a certain wavelength grid provided by the BBM spectrometer. Modern spectrometers can perform measurements at several hundreds of wavelength points.

taReo demonstrates unparalleled computational efficiency, offering several remarkable features:

- The computational speed is exceptionally high, even when dealing with numerous layers. There is no need to interrupt the deposition process to re-optimize the remaining layers or obtain characterization results.

- The software allows for an unlimited number of points in the wavelength grid, enabling precise and detailed analysis across a wide range of wavelengths.

- There are no limitations on the number of design layers that can be utilized in the software. Complex coating designs can be easily accommodated.

- The software provides flexibility in material selection for the coating design process.

What can be done with taReo?

- taReo can be employed to perform inline analysis of measurements and compare them with expected theoretical spectral characteristics. Through this analysis, it becomes possible to determine the appropriate termination time for layer deposition.

- taReo can perform inline characterization based on inline measurement data. Based on the characterization results, deposition parameters can be adjusted and the process can be improved in order to achieve planned spectral characteristics.

- taReo can perform inline reoptimization of the rest of the layers in the case when the deviations between expected theoretical characteristics and experimental characteristics grow.

taReo has been successfully tested

The implementation of taReo as an additional tool into the MOCCA+® software has been performed successfully. Learn more...

What companies/institutes/individuals can be interested in taReo?

- Companies producing vacuum chambers equipped with broadband monitoring. taReo will be OEM (Original Equipment Manufacturer) in this case.

- Companies/institutes manufacturing optical coatings and having deposition plants equipped with broadband monitoring.

- Companies/institutes interested in building their own BBM simulation systems in order to search for designs with higher production yield.

- Companies/institutes developing thin-film technologies.

- Companies/institutes/individuals developing their own thin-film software (design, analysis, characterization, reverse engineering).